Geosystems Engineering

| HOME | PETROPHYSICS | SEISMIC | STATIC MODEL | DYNAMIC MODEL | ANALYTICAL METHODS | PROJECT PLAN | CONTACT | ABOUT |

NEWS

Petrophysic-Consultants

Geosystems Engineering

_________________________________________________________________________________

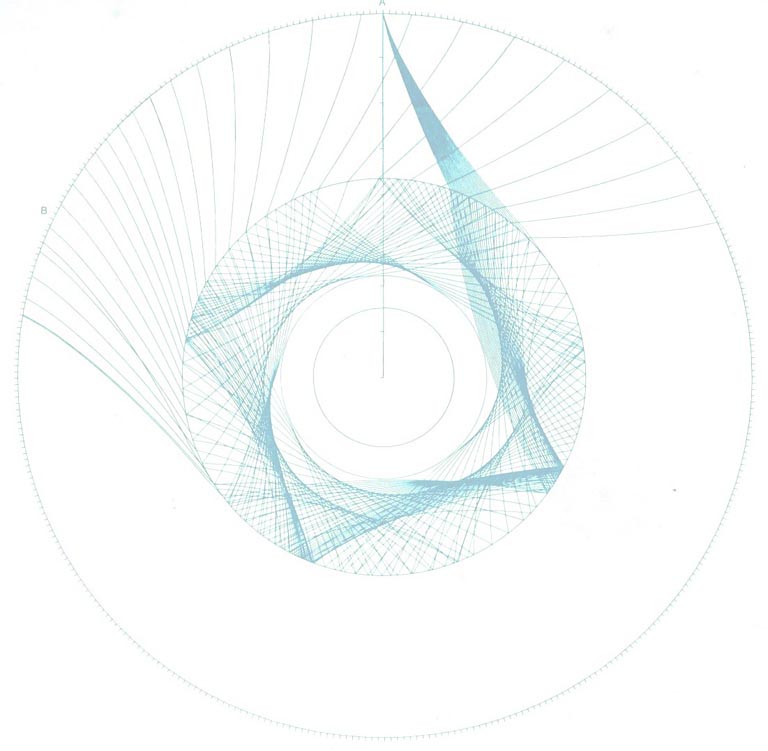

SPSI : SPATIAL PETROPHYSICAL-SEISMIC INVERSION

Local Petrophysical equations can be transformed into Density and Velocity parameters.

These can be spatially distributed with the SPSI method on the the 3D Seismic Volume

together with other Related Petrophyscal Properties like Water Saturation or Resistivity.

This increases resolution and accuracy in the interpretation process.

DRho/Rho Baseline Model Rho_be Model with Resistivity effect

_________________________________________________________________________________

2014

SPSI

SPATIAL PETROPHYSICAL-SEISMIC INTEGRATION

PETROPHYSICAL INVERSION and PETROPHYSICAL-SEISMIC INTEGRATION

An innovative patented method to unify the Seismic and Petrophysical theory and a new step to the implementation of a wide maximum resolution Static Model, positioning all Petrophysical Static and Dynamic Properties on the 3D Seismic Volume.

DETERMINISTISCHE UND STOCHASTISCHE METHODE ZUR BERECHNUNG, VERBREITUNG UND INTERPRETATION

PETROPHYSIKALISCHER MIKRO-EIGENSCHAFTEN UND MAKRO-EIGENSCHAFTEN ALS PETROPHYSIKALISCH-SEISMISCHE ATTRIBUTE IM „3D SEISMIC VOLUME“ FÜR INTERPRETATIONSZWECKE.

ABSTRACT

Diese Erfindung beschreibt eine Methode zum Prozessing, zur Inversion und zur

Integration von seismischen und petrophysikalischen Daten. Diese Methode führt

zur Implementierung eines Modells für die seismische und petrophysikalische

Interpretation, um die geologischen Strukturen und die Physik der Gesteine

im Untergrund zu beschreiben. Sie ist eine Innovation für die Darstellung

petrophysikalischer Parameter und dessen Beziehungen zu seismischen Attributen

auf dem „3D Seismic Volume“.

Die Methode vereint Seismik und Petrophysik in einer einzigen Theorie.

Petrophysic-Consultants

Geosystems Engineering

_________________________________________________________________________________

2013

INHOUSE SEISMIC INVERSION AND INTERPRETATION

Petrophysic-Consultants in Munich offers innovative SEISMIC INVERSION AND INTERPRETATION services.

This services are offered in Munich with modern professional software and scientific competence

_________________________________________________________________________________

2011

DDS

" DEEP DIRECTIVITY SYSTEMS "

A

new patented technology for Deep Geothermal Systems, a key for the future of the renewable energy.

DDS is a new scientific innovation.

A method for the universal development of geothermal projects not only in

areas of high geothermal gradient, but in every part of the

world.

DDS - " DEEP DIRECTIVITY SYSTEMS

"

A

TECHNOLOGICAL INNOVATION WHICH CHANGES THE FUTURE OF GEOTHERMAL ENERGY

PRODUCTION AND ENABLES NOVEL EFFICIENT APPLICATIONS USING OIL AND GAS

EXPLORATION AND PRODUCTION TECHNOLOGY IN GEOTHERMAL ENERGY DEVELOPMENT.

“Using

these technologies, according to DDS concepts, it becomes possible to

circulate water within predefined flow lines, in continuous

flow and in a closed

system, for more than 100 kilometers, while keeping most of

or all the flow line

system below a predefined depth.

This depth could be, for example 3000 m and more, so that

the water flow is for

most of the flow path length in a formation, the temperature

of which is above

110 degrees Celsius, which is an ideal minimum temperature

level enabling

the production of electrical power.”

DDS

(Deep Directivity Systems) is an innovation in the field of geothermal

exploration and production. It was originally presented a few months ago

by GeoNeurale as a technology to be operative developed by

Petrophysic-Consultants, but it appears that up to now few people really

recognized the

enormous potential thereof for the deep geothermal and oil and gas

exploration and production.

DDS comprises a set of state of the art reservoir

development techniques adapted for use in deep geothermal energy

development projects. In other words, DDS comprises combinations of

existing technologies from the oil and gas exploration and production

field, which are transferred to the development

of deep geothermal energy projects, enabling boosting the flexibility and

efficiency of deep geothermal projects.

In this article, a few visionary example

applications are presented and DDS main technological aspects are

conceptually explained before the background of the state of the art of

technology used in deep geothermal projects.

The technology base for DDS (or: What are its roots and

bases ?)

A

first main technology basis of DDS is horizontal drilling, an application

that has been developed in the past to improve recovery in oil and gas

reservoirs.

The first horizontal well was drilled in 1929 and at

that time the potential of this technology was not fully encompassed. At

present, it is possible to drill boreholes into the earth subsurface with

lengths greater than 12000 m using horizontal drilling technology.

Horizontal drilling creates a continuous borehole, and hence a regular

flow-line from the surface to the well shoe.

A second main technology basis of DDS comprises

reservoir stimulation techniques including hydraulic fracturing, suitably

adapted to make permeable the rock formations found at the typical depths,

ca. 3000 meters or more, of deep geothermal reservoirs.

DDS is a system of concepts using horizontal

drilling and hydraulic reservoir fracturing

for creating virtually indefinite lengths of downhole flow line connectivity.

The significance of DDS will be described together with a few examples of

the potential thereof.

Using these technologies, according to DDS concepts, it

becomes

possible to circulate water within

predefined flow lines, in continuous

flow and in a closed system, for more

than 100 kilometers, while keeping

most of or all the flow line system below

a predefined depth.

This depth could be, for example 3000 m

and more, so that the water flow

is for most of the flow path length in a

formation, the temperature of

which is above 110 degrees Celsius, which

is an ideal minimum

temperature level enabling the

production of electrical power.

What can DDS make possible?

Envisage

a futuristic mind game to describe the potential of our DDS technology and

see the advantages which this could bring in the future.

Imagine that new drilling methods have become

available for drilling a well in a few, possibly only one day.

With such drilling efficiency (ROP) and using the

concepts of DDS technology, it would be possible to drill, within a few

years, a deep flow-line system connecting Europe to America and/or Europe

to China with flow lines running steadily

below 3000 m or more of depth and back to Europe to the same point, where

the hole was started to be drilled as an injection well (initial

spud-point).

In this way, it would be possible to create an

intercity system of geothermal power plants, deployed for instance along a

highway for supplying electricity-driven cars with electric energy.

This is only one example of how a deep geothermal

project could be indefinitely extended using DDS technology.

Between theory and technical realization, the

following challenging factors need to be solved resp. overcome:

1. Hydraulic pressure loss would be directly

proportional to the thermal efficiency and their ratio would need to be

optimized.

2. In this respect, the positioning of downhole

pumps would be a critical issue.

The above is only an example of extreme (and

expensive) solutions that would require further technological innovations

to achieve faster drilling.

However the concept and technology of DDS systems

are available already now.

Smaller projects employing DDS technology at the city

scale are already

now an economically feasible and technically realistic solution

for

intercity geothermal power-plants having zero CO2

emissions, producing

enough energy to supply the energy need of two small towns.

DDS

technology results from the scientific challenge of the firstly mentioned

author and from many years of study and experience in the oil and

geothermal exploration industry.

Bringing DDS technology to application will require

a comparable level of creativity based on an attitude of scientific

integrity and the integration of a specific scientific and technological

philosophy.

STATE OF THE ART IN GEOTHERMAL ENERGY PRODUCTION

Up

to now, deep geothermal energy was mainly exploited using the following

two

methods:

-

Hydrogeothermal systems

and

- Hot Dry Rock (HDR) systems.

Hydrogeothermal systems are confined, however, to

special areas,

corresponding to a relatively small part of the

earth surface. Their utility is therefore very limited.

Hydrogeothermal systems are mostly associated with

the presence of factured and karsted

carbonate formations, which are scarcely distributed. Moreover, the risk

of project failure in hydrothermal reservoirs is not negligible due to the

high costs of required efficient seismic investigations and the

uncertainty of geophysical methods to identify the presence of water

In Hot Dry Rock (HDR) projects, water is circulated through an injection

well, the respective HDR formation and a production well, from which the

water is, after extraction of heat energy using heat exchangers at the

surface, re-injected into the injection well. In particular, the

water is pumped into the injection well and down to the shoe. Between the

shoe of the injection well and the shoe of the production well, a system

of natural fractures is required to provide a natural flow stream for the

water circulating from the injection well and the production well. Upon

flowing through the rock porosity / permeability system, the water is

heated due to its contact with the hot rock matrix/fluid interface and

transports the according heat energy to the surface.

Generally, the overall heath energy extraction at depth must be

compensated by the natural geothermal heat flow, which radiates

principally from the earth mantle outwards to the earth crust.

If a natural system of fractures does not exist or is inefficient to

provide the required flow rate in order to run the geothermal energy

extraction and production process, then an artificial fracture system must

be provided through downhole fracturing operations.

In the producer well, downhole pumps provide the flow, in order to pump

the hot water from the shoe to the surface. Proper downhole filters have

to be installed for sand and solid control.

The hot water flowing to the surface passes through a heat exchange

system,e.g. of a Kalina cycle or other type of power plant. At

higher

temperatures, e.g. above 150 degree Celsius, the water will partially flow

in the vapor phase, which increases its concentration at increasing

temperatures.

In reservoirs with temperatures around about 300 to 400 degree Celsius,

the flowing phase is only vapor. This vapor can directly flow through the

turbines of the power plant.

The water/vapor flowing out of the power plant is re-injected into the

thermal reservoir through the injection well and the circulation cycle

starts again.

The difficulty of a HDR project is to manage and provide downhole an

essentially horizontal system of fractures which are hermetically confined

in order to avoid a dispersive flow.The flow directivity must be confined

from the injector to the producer well. If there is not a natural

reservoir directly providing high pressure steam and the necessary

permeability, then fracture or stimulation operations must be applied in

order to provide a suitable connectivity flow system in the geothermal

reservoir.

In a fracture stimulation operation, water is pressed at high pressure

cycles downhole and further injected through perforations in the well

casing into the surrounding reservoir rock formation in order to overcome

the minimum horizontal stress field (Sigma-3). This will generally produce

a fracture that is perpendicular to Sigma-3 and in the Sigma-1/Sigma-2

plane, i.e. in a sub-vertical fracture.

A difficult task in controlling a fracture process relates to the

difficulty of identifying with the required precision suitable

geomechanical parameters allowing determining the heterogeneity of the

rock

matrix/porosity system and the direction of the closure stress.

If the fracture stimulation process is not properly planned and the

parameters influencing such process are not sufficiently determined in

detail, control on the fracture directivity, especially in the far-field

region with respect to the downhole center of the fracturing operation

water injection might be lost. As a consequence, in the production phase

the flow might not be focused in the desired direction and this might

strongly reduce the geothermal energy recovery at the producer well.

The artificial fracture system might also intercept natural fractures,

which might lead to water dispersive flow, fluid losses and system

inefficiency.

In the absence of effective stress confinement, (barrier) layers above and

below the fracture horizon, the vertical fracture propagation might reach

permeable layers above with lower temperature or high permeability layers,

which in turn might lead to flow dispersion.

For running an efficient geothermal cycle, a flow rate of more than 100

liter/second at temperatures possibly above 110 degree Celsius are needed

to this aim, dispersive flow is a serious thread in geothermal production.

DDS SYSTEMS: A STEP AHEAD IN GEOTHERMAL SOLUTIONS

Deep Directivity Systems (DDS) can be defined as a

combination of (latest and/or future) drilling, directional drilling

control, reservoir stimulation,

extensive

fracture generation and well completion technologies.

The drilling technologies are for drilling multi-directional wells and/or

systems of mutually interconnected wells and/or well systems, which are

planned and directed to reach, from possibly only one or more spud points,

interconnect and optimally permeate a plurality of deep geothermal

reservoirs (formations) from which the geothermal energy will produced to

the possibly only one spud point at the earth surface, where sufficient

geothermal power is supplied from the plurality of reservoirs so that an

electric power plant can be operated continuously.

The directional drilling control technologies are for controlling the

complex subsurface path of the drill head. The reservoir stimulation and

new fracture generation technologies are for permeably connecting

respective large volumes of a deep geothermal reservoir formation to the

plurality of respective wells which permeate the reservoir formation.

The well completion technologies are for completing the casings which are

introduced into the wells and for providing in a casing wall the apertures

required to provide the water flow communication from the interior of the

respective well (injector) to the surrounding geothermal reservoir and

further another well (producer) penetrating the same reservoir, thus

closing a water flow loop for extracting geothermal energy from the

respective reservoir and comprising the respective injector well, said

reservoir and the respective producer well.

Having examined case studies of some failed geothermal projects, the DDS

concept has been invented and developed conceptually with the aim to

optimally control the flow directivity in the geothermal reservoir at the

maximum possible resolution scale and efficiently and hermetically close

and interconnect respective water flow circulation systems reaching one or

plural geothermal reservoirs, thereby avoiding dispersion by waterflooding.

A special workflow of reservoir characterization studies has been setup,

as a specific program for the planning and implementation of DDS projects.

One of the relevant advantageous features of DDS is that the water flow circulation system can be designed, re-designed and extended such that the energy conversion system provided at the earth surface can be adapted to virtually any desired scale in terms of power and efficiency.

For example, if initially a small scale project comprising a 2 Megawatt electrical power plant unit has been realized, this project can be virtually indefinitely extended, e.g. by adding new component units at the earth surface location for increasing the total power to 10, 100 or 1000Megawatt and by developing new deep geothermal reservoirs and flow-connecting these to the respective earth surface location.

Using the concepts of DDS, a deep geothermal project can be planned conceptually as a predefinable, locally optimized, turn-key system, in which the dimension and efficiency can be designed already in the pre-planning phase, thereby reducing the uncertainty and project risk to a minimum level.

Compared to hydrothermal projects, which are limited to only a few areas in the world, and to Hot Dry Rock projects, which generally bear a considerable risk, projects designed using DDS system concepts can be realized in more than 95% of the earth's surface, which renders to such projects the maximum possible design flexibility and a vast spectrum of applications.

In

result, the novel DDS concept for designing deep geothermal projects will

bring increased project efficiency and lower risk with respect to any

other kind of geothermal projects.

The novel DDS concept invented by GeoNeurale represents a great evolution

in geothermal technology and in the renewable energy sector.

By

Angelo Piasentin (GeoNeurale, Munich/Germany)

and

Dr. Stephan Klauer (SK-Patent Law Office, Munich/Germany)

www.geoneurale.com

www.petrophysic-consultants.com

__________________________________________________________________________________________________________________________________

DDS

DEEP DIRECTIVITY SYSTEMS

For Informations

Email: info@GeoNeurale.com

Tel 089 8969 111 8 Fax 089 8969 111 7

_____________________________________________________________________________________________________________

2010

Petrophysic-Consultants new integrated reservoir characterization concept for geothermal reservoir analysis is operative and was applied for the deep geothermal project in Koenigsdorf.

Petrophysic-Consultants is the first group in this sector to apply a full inhouse integrated petrophysical analysis to evaluate the target area and support the seismic interpretation.

_____________________________________________________________________________________________________________

_____________________________________________________________________________________________________________

_____________________________________________________________________________________________________________

__________________________________________________________________________________